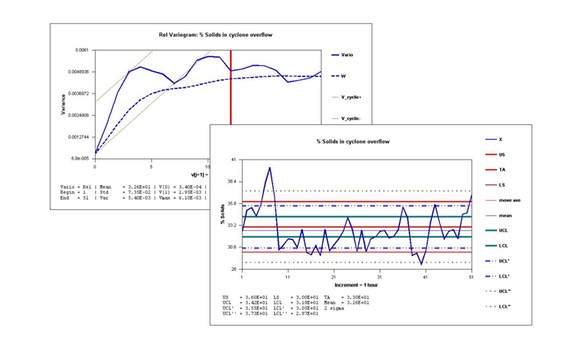

Your data has been meticulously gathered and stored at considerable expense. It has value... don't let it gather dust!

With EMPV™, you can put that data to work and determine the source of variability while controlling key process parameters.

EMPV™ is an effective tool used by managers to investigate an operation's control of key process parameters.

Such investigations of process variability minimize negative consequences resulting from:

- Poor quality products

- Poor metal recovery

- Energy consumption

- Chemical reagents consumption

- Excessive maintenance, or lack of it…

- Costly process over-correction

- Unrealistic goals

- Inter-departmental disagreements

- Focus on negative effects

EMPV™ Aplications:

- Feed size distribution to a floatation plant

- Gold leaching tank's cyanide content

- Slag metal content

- Copper concentrate's moisture content feeding a smelter

- Regular plant pollutant discharge

- pH across a CIL or CIP gold leaching process

- Pyrometallurgical furnace temperature

- Impurities in copper cathodes

- Temperature impacts caused by a misaligned SAG Mill axle

- Gold loaded carbon losses through a CIL or CIP plant, etc…